How to Improve Battery Pack Tab-to-Terminal Connections

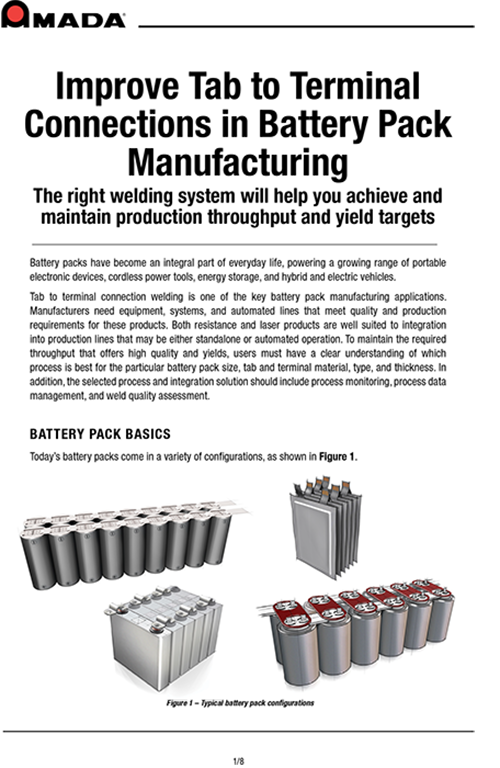

Battery packs are integral to our everyday use of portable electronic devices, cordless power tools, and hybrid and electric vehicles. Robust tab-to-terminal welding, therefore, is critical to battery pack manufacturing success. This white paper provides guidance on how to choose the right welding process based on battery pack size, tab-and-terminal material, type, and thickness to achieve and maintain high throughputs, quality, and yields.

Read this white paper and learn:

- How to choose the right welding technology for optimal throughput and yield

- Advantages of resistance welding

- Advantages of laser welding

- How to automate your welding

Please fill out the form to download whitepaper.

SPONSORED CONTENT

Informa values your privacy. To fully understand how we use your data, please see our Privacy Policy.